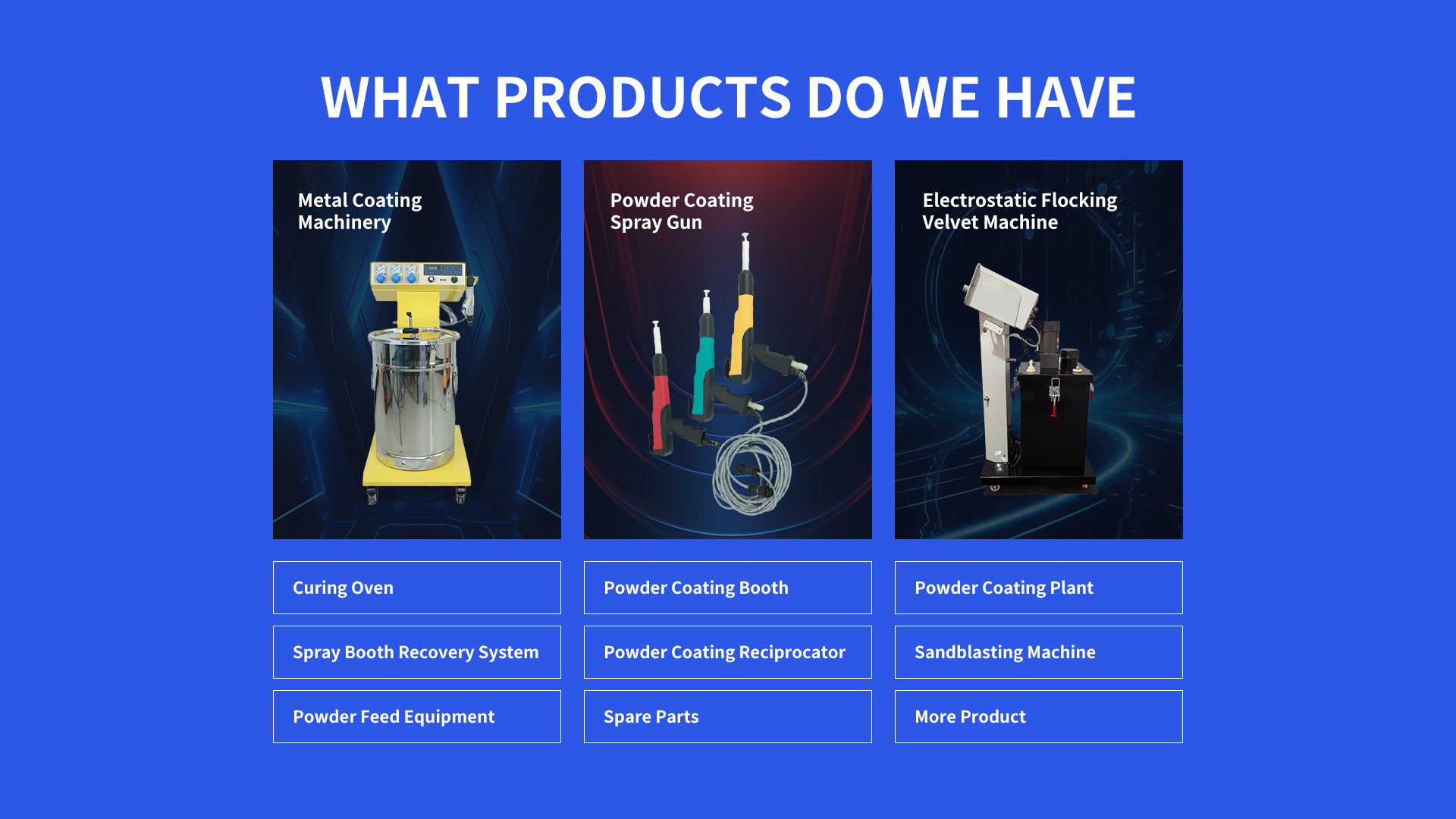

1. Powder Coating Spray Gun Components and Structure

A Powder Coating Spray Gun comprises a nozzle, powder container, electrostatic generator, and airflow regulator. Modern 2025 models integrate IoT sensors for real-time performance tracking. The electrostatic charge ensures uniform adhesion, while ergonomic designs reduce operator strain. High-end variants feature automatic powder recovery systems to minimize waste.

2. Applications of Powder Coating Spray Guns

These guns dominate automotive, aerospace, and furniture industries for coating metals like steel, aluminum, and magnesium alloys. Emerging uses include renewable energy equipment (solar frames, wind turbines) and EV components, offering corrosion resistance and aesthetic finishes.

3. Powder Coating Spray Gun Pricing

Prices range from 250(basicmanualguns)to8,000+ (industrial IoT-enabled systems). Mid-tier options (1,000–3,500) suit SMEs with features like adjustable kV settings and powder recycling. In 2025, eco-friendly models command a 15% price premium due to sustainable material demand.

4. Proper Use of Powder Coating Spray Guns

Prep surfaces with degreasing and sandblasting. Set voltage to 40–100 kV for optimal electrostatic adhesion. Maintain a 6–12 inch distance, using steady, overlapping motions. Post-spray, cure coatings at 320–400°F for 10–20 minutes. Clean nozzles immediately to prevent clogging.

5. Choosing the Right Powder Coating Spray Gun

Prioritize workload (manual for low volume, automatic for batch jobs) and material compatibility. Look for voltage adjustability, IoT diagnostics (2025 trend), and warranty coverage. Test ergonomics to ensure operator comfort during prolonged use.

6. Safety with Powder Coating Spray Guns

Wear N95 masks, anti-static gloves, and goggles to avoid inhaling ultrafine particles. Install explosion-proof ventilation systems and ground all equipment. Store powders in cool, dry areas away from ignition sources.

7. Design Efficiency of Modern Spray Guns

2025 models reduce energy use by 25% via AI-driven airflow optimization. Modular designs allow quick part replacements, while recyclable materials align with circular economy standards.

8. FAQs on Powder Coating Spray Guns

Q: What metals suit powder coating spray guns best?

A: Steel, aluminum, and alloys achieve flawless finishes; pre-treat non-conductive materials like plastics.

Q: Can I reduce overspray waste?

A: Yes, advanced guns reclaim 90%+ overspray via closed-loop systems.

Q: How long does gun maintenance take?

A: Daily cleaning takes 10 minutes; deep clean weekly.

Q: Are automated guns worth the cost?

A: For high-volume tasks, automation cuts labor costs by 40%.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com